THE STORY OF THE CP1000 R-1

The Revolutionary Tool from Electrical Product Innovation, Inc.

Tommy D had literally spent his entire life in the electrical trade. His father was a union electrician his entire life and Tom followed suit working for the same company as his father. As soon as he was eligible, he apprenticed at his local IBEW.

Now in his fifties, the career that had been very good to him for so long became more challenging. The physical demands from a professional life pulling wires, lifting piping, connecting junction boxes and moving large cable reels had already taken a toll. Five shoulder surgeries couldn’t repair the long term damage he was facing and a shoulder replacement surgery was scheduled.

Tom had always been physically active outside of work. Strong and fit he thought the last thing he would face at this stage of his career would be a condition that could reduce his effectiveness as a professional.

He wondered first, how much of his professional life contributed to his physical problems; and two, what could be done about it.

He began researching how his life’s work has impacted his body.

In his research, Tom discovered just how ergonomically bad wire pulling was for the body.

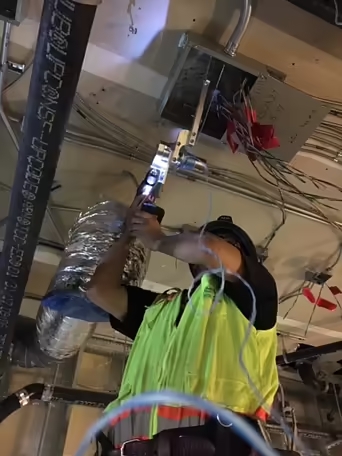

The placement of junction boxes in ceilings, conduits in gutters & panels, light standards, and underground conduits puts your body in an awkward, unnatural position when trying to pull. This causes excessive strain on the shoulders, arms, back and wrists.

According to the US Department of Labor, over 31,000 workmen are injured each year from stress and strain injuries caused by lifting, reaching, pulling, and bending. This is such an important issue that OSHA has even provided very specific guidelines.

Often with the pressures of the job, guidelines are pushed aside as impractical. During this time the only options for wire circuit pulling have been either:

Pulling by hand with rope, mule tape, fish tape or string Using a big, bulky puller not really engineered for branch circuits and time consuming to manage Ultimately, they are both poor choices in an environment where both efficiency and safety are important. Very often space constraints also make simple pulling nearly impossible. He had used very large tuggers in large projects before. He wondered whether there was a smaller, portable and compact electric winching system for branch circuit wire.

Although 80% of all wire pulled on a job site is branch circuit wire, there actually wasn’t a tool available for circuit pulling. So he got to work.

He knew the tool had to be convenient and easy enough to use so the time for setup and engagement didn’t take longer than the circuit puller itself.

It had to be powerful. Wire pulling becomes increasingly difficult as the wire moves through the conduit. Each pull adds more weight to the successive pull…every pull harder than the next. Gearing for maximum torque would be critical for the new circuit puller he would design.

For months he explored different design ideas with unique gearing ratios. Hand cranking wasn’t practical and was physically demanding. The basic design idea still made sense but it needed power and would be best if it was handheld.

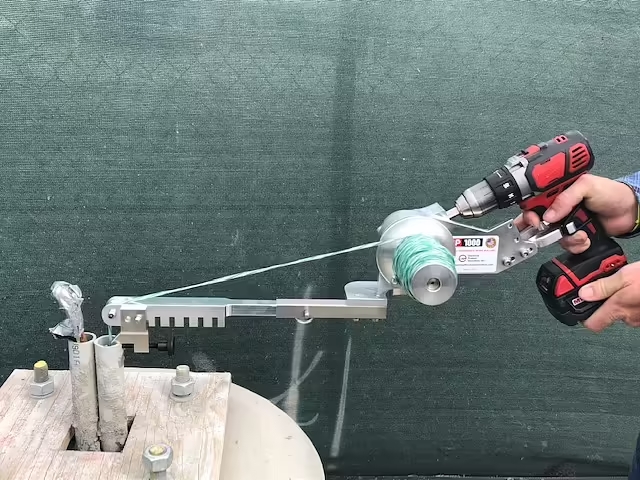

Then he came up with the idea of having the basic cordless drill motor power the circuit puller. Could the drill motor generate enough torque in combination with the wench-like process to provide a continuous pulling pressure to deliver a successful wire pulling experience?

The gearing was critical.

After extensive search and experimentation he discovered the perfect combination of speed, torque and energy transfer. He had a working prototype for a circuit puller. But he was far from finished.

Working with his partner Joe Gerardo, a long time electrical product engineer, they realized that the winding process is only part of the solution. The circuit puller needed stability to handle the back strain of heavy wire. Much like a fishing rod does. So he began experimenting with various extension arms – straight, articulating, short and long – finally landing on the right combination to give the user the highest confidence and stability…and greatest results.

Field tests had to follow so Tom and Joe shared it around the electrical community. Most guys thought it was a good idea but were skeptical at first. That was until Joe threw a rope to a 250 pound electrician, told him to sit on the floor, and then pulled him across the room using just the circuit puller!

But they believed!

The handheld circuit puller worked!

After field tests and minor modifications, the handheld circuit puller did exactly what it was supposed to do and even more. Tom discovered that the gearing would deliver up to 1000# of torque and could easily handle multiple wire batches of branch circuit, as well as three and four wire pulls of very heavy gauges.

Tom knew he had a game changer with the potential to change how the trade handles wire pulling. He knew it would help his fellow electricians extend their careers and lessen injuries. He also knew it would help contractors reduce the EMR rates that have been growing and providing greater financial burden on the bottom line.

Many decisions followed. How to manufacture? How to market and distribute?

With a commitment to manufacture and produce in the US, Tom selected a local machine and tooling manufacturer with a history of high quality output and error free work.. He believes in keeping and growing US manufacturing, knowing full well if he went overseas the product cost would likely be reduced, but so might quality and responsiveness.

With a product launch at the NECA show in Seattle in late 2017 and

adoption growing across the country for the circuit puller, Tom’s hope is that every electrician can use this tool to extend their careers and improve their field working conditions.

He also encourages his fellow electricians to follow their hunches and think outside the box. The best ideas come from the field where the guys that are actually doing the work build creative solutions every day. Keep your eyes out for opportunities and challenges that can improve our trade. New ideas are borne every day. Maybe your idea is the next one!

See the complete article featured in Mike Holt's Newsletter here.

We are proud to claim that the CP1000 R-1 Handheld Circuit Puller/Tugger is the Original USA patented handheld circuit puller/tugger. Made in America and Proud of It! Insist on the CP1000 R-1!